Introduction

The use of silver in the electronics industry has become essential due to its exceptional electrical conductivity and thermal properties. Silver plays a crucial role in electronic devices like circuit boards, switches, and contacts, offering superior performance compared to other metals like copper. Its antimicrobial properties also make silver an ideal choice for healthcare-related electronics. As the electronics demand continues to grow, silver is widely utilized in various applications, from consumer gadgets to industrial equipment, where its unique properties ensure reliability and longevity.

Considering silver’s importance in the industry, its role extends beyond just conductivity. Silver is also used in solar panels, printed electronics, and even in emerging technologies like silver nanowires. Although the price of silver may fluctuate, its necessity in advanced electronics will likely drive the need for silver in the future. With applications expanding and the electronics industry evolving, silver’s value continues to rise, offering beauty, value, and performance across numerous sectors.

Key Takeaways

Silver’s exceptional electrical conductivity makes it an essential material in modern electronics, offering superior performance compared to other metals like copper.

Silver plays a critical role in various electronic devices, including circuit boards and contacts, due to its resistance to corrosion and oxidation.

The growing demand for silver in the electronics industry is driven by its diverse applications, including in solar panels, printed electronics, and medical devices.

Silver nanoparticles enhance the efficiency of solar panels by improving conductivity, making them integral to renewable energy technologies.

Silver’s thermal and electrical conductivity ensures reliability in high-performance applications like telecommunications and aerospace.

While silver offers numerous advantages in electronics, environmental concerns about its finite supply and potential ecological impact are important considerations.

How Silver in Electronics Revolutionizes the Electronics Industry

The use of silver in electronics is transforming the electronics industry due to its superior electrical and thermal conductivity. As a precious metal, silver plays a crucial role in electronic devices, from circuit boards to switches and contacts. Silver is used in various components, thanks to its corrosion resistance and reflective properties. With the demand for smaller and more efficient electronic devices, silver usage continues to grow, especially in the production of printed circuit boards and electrical connections. Its ability to carry electrical current with minimal resistance makes it indispensable in modern technology. Considering silver’s properties, it has become a vital material in the creation of innovative devices.

Why Silver is Essential in the Electronics Industry

Exceptional Conductivity

Silver’s electrical conductivity is unmatched compared to gold or copper, making it the top choice for circuit boards and electronic devices. Its ability to carry electrical current with minimal resistance ensures superior performance, especially in high-demand applications.Thermal Properties

Silver’s thermal conductivity allows for better heat dissipation, which is crucial in devices like smartphones and computers. While gold and copper are effective, silver’s thermal management capabilities help maintain device longevity and efficiency.Corrosion Resistance

Unlike copper, which is prone to oxidation, silver’s resistance to corrosion makes it ideal for sensitive components in electronic circuits. This enhances the durability and performance of the devices, especially in extreme conditions.Cost-Effectiveness in Certain Applications

Although silver is more expensive than copper, it requires smaller amounts to achieve superior performance. This makes it a cost-effective option in specific applications, particularly in the growing fields of printed electronics and solar panels.Wide Applications in High-Tech Industries

Silver is utilized in high-tech applications where precision is essential, such as medical devices and renewable energy technologies. Its usage in solar energy, RFID tags, and light-emitting diodes further underscores its versatility in modern electronics.Sustainability and Future Prospects

The growing demand for environmentally friendly technologies, like solar energy, relies heavily on silver. Additionally, innovations in silver nanowires are paving the way for flexible electronics, indicating that silver will continue to play a pivotal role in the future of electronics.

How Silver’s Exceptional Conductivity Impacts the Electronics Industry

Silver’s conductivity is unmatched in the world of electronics, allowing it to carry electrical current with minimal resistance. This makes silver a key material in the creation of smaller, more efficient electronic devices. Its thermal and electrical conductivity helps maintain device reliability, preventing overheating and ensuring smooth operation. This is particularly important in products like smartphones, tablets, and other consumer electronics where performance is crucial. The use of silver in electronics ensures that devices continue to improve in both performance and longevity, meeting the growing demand for cutting-edge technology.

The Growing Demand for Silver in the Electronics Industry

As consumer electronics become increasingly advanced, the demand for silver is steadily rising. Silver’s unique properties, such as its corrosion resistance and ability to carry electrical signals efficiently, make it an ideal material for everything from circuit boards to electrical connections. This precious metal also plays a crucial role in high-performance applications, such as those found in renewable energy and medical devices. The electronics industry depends on silver’s exceptional properties to create more reliable and efficient devices. This trend is expected to continue as the industry expands and evolves.

The Role of Silver in Circuit Boards and Metal Applications

Silver plays a vital role in the development of circuit boards and other metal applications in the electronics industry. Due to its exceptional electrical and thermal conductivity, silver is ideal for creating solder and conductive coatings. The use of silver in circuit boards ensures long-term reliability and performance. Its resistance to oxidation and corrosion makes it perfect for switches, contacts, and other critical components in electronic circuits. This unique metal enhances the efficiency of modern electronics, allowing for smaller, more compact designs that are still highly functional. As technology advances, the demand for silver in electronic applications will continue to rise.

Case Study: Silver’s Role in Circuit Boards for the Automotive Industry

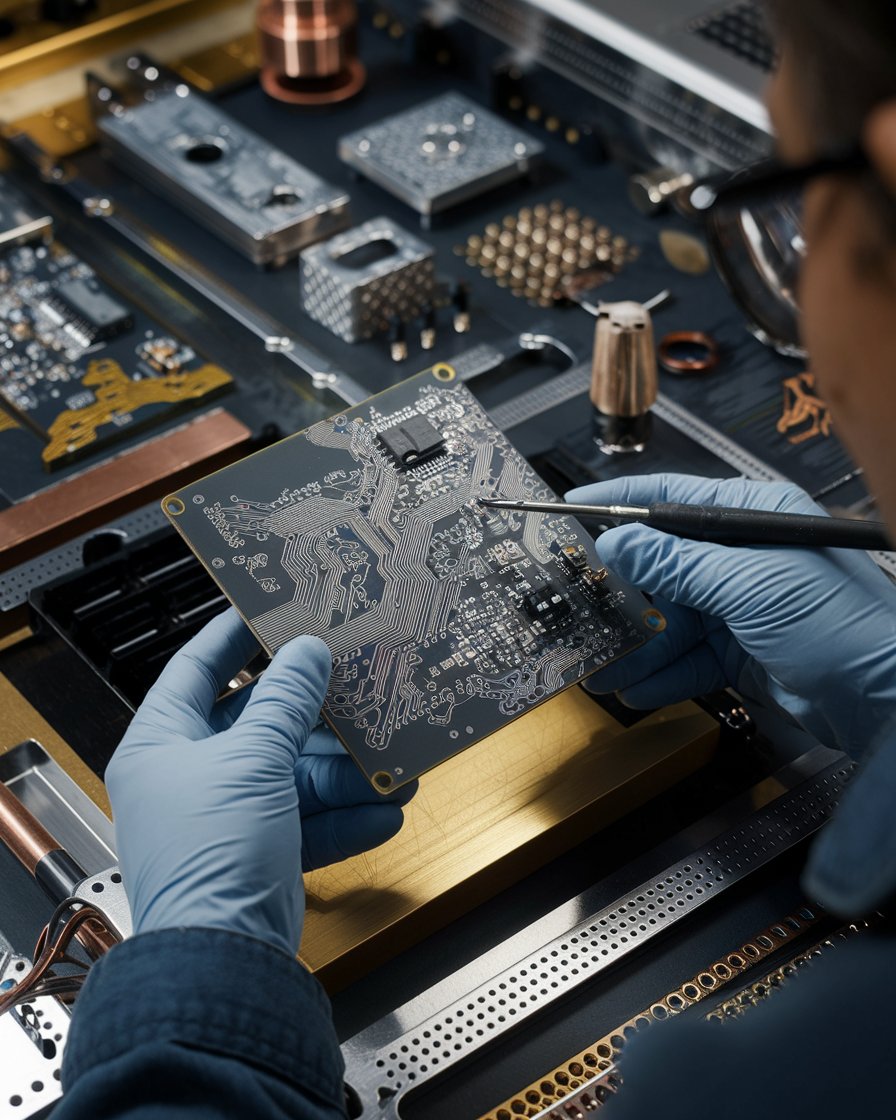

In 2018, a major global automotive manufacturer faced reliability issues with their circuit boards, which were initially made using copper. The frequent failure of the boards, particularly in high-temperature environments like engines, was attributed to copper’s vulnerability to oxidation and corrosion. To resolve the issue, the company switched to silver-coated circuit boards.

Silver’s superior thermal conductivity and resistance to oxidation allowed the circuit boards to withstand extreme heat and environmental conditions without degradation. This change resulted in a significant reduction in component failure, increasing the reliability and longevity of the vehicles. The company also noted that the silver-based solution allowed for the development of smaller and more efficient circuit designs, improving overall vehicle performance.

Why Circuit Boards Rely on Silver for Durability and Performance

Circuit boards in modern electronics require materials that are both durable and reliable. Silver, with its resistance to corrosion and oxidation, provides these essential qualities. Silver coatings on circuit boards help ensure that electrical connections remain strong over time, preventing failures in crucial electronic components. Silver’s ability to maintain its conductive properties under extreme conditions makes it an ideal choice for circuit boards used in demanding environments like automotive or aerospace industries. As technology pushes the boundaries of what electronics can do, silver will continue to be a critical material in ensuring the longevity and performance of circuit boards.

Silver’s Application in Metal Coatings for Advanced Electronics

Silver’s use in metal coatings for electronic devices enhances both functionality and longevity. By applying a thin layer of silver to switches, contacts, and other key components, manufacturers can reduce the risk of corrosion, ensuring the device performs optimally over time. This practice is common in the production of high-performance electronics, where reliability is crucial. The metal’s thermal and electrical conductivity also helps dissipate heat, preventing damage to sensitive components. As the need for more durable electronics grows, silver’s role in metal coatings will become increasingly important.

Why Silver is Preferred Over Copper in Electronic Circuits

While copper has been widely used in electronics, silver is increasingly favored for its superior electrical conductivity. Silver’s status as a precious metal, combined with its ability to resist oxidation and corrosion, makes it a valuable material for electronic circuits. Its usage is particularly notable in applications requiring high performance and reliability, such as in solar panels and high-frequency electronic devices. Silver’s ability to conduct electrical signals with minimal resistance also makes it the top choice for creating smaller and more efficient electronic components. As the electronics industry continues to evolve, the use of silver will likely become even more widespread.

How Silver Outperforms Copper in Electrical Conductivity

Although copper is widely used in electronics, silver’s superior electrical conductivity makes it a better option for high-performance applications. Silver allows for more efficient electrical signal transmission, reducing energy loss and enhancing the overall performance of electronic devices. This is especially important in industries such as telecommunications and renewable energy, where reliability and efficiency are critical. Silver’s ability to withstand environmental factors such as corrosion also gives it a significant advantage over copper. As demand for more advanced technology increases, silver is expected to continue outperforming copper in key applications.

The Role of Silver in Reducing Oxidation in Electronics

One of the reasons silver is preferred over copper in many electronic applications is its ability to resist oxidation. Oxidation can cause electrical connections to degrade over time, reducing the effectiveness of electronic circuits. Silver’s natural resistance to this process ensures that devices remain reliable, even in challenging environments. This makes silver a top choice for switches, contacts, and other components that are exposed to the elements or high levels of wear. As electronics continue to evolve, the role of silver in maintaining device longevity and performance will only become more critical.

“Silver is the best conductor of electricity, bar none. Its superior conductivity makes it a crucial component in our most advanced technologies.” – Michael Faraday

Silver Nanoparticles and Their Growing Importance in Solar Panels

Silver nanoparticles are playing an increasingly important role in solar panels and other renewable energy technologies. These nanoparticles enhance the efficiency of solar panels by improving the conductivity of the thin layer used in photovoltaic cells. Silver’s reflective and conductive properties make it a perfect fit for capturing solar energy and converting it into electrical power. As demand for solar energy continues to grow, silver’s role in these technologies will become even more crucial. The electronics industry is relying on silver’s unique properties to meet the increasing demand for environmentally friendly energy solutions. Silver will continue to be a key player in renewable technologies.

Silver Nanoparticles in Photovoltaic Cells for Solar Energy

Silver nanoparticles are revolutionizing the solar energy industry by significantly improving the efficiency of photovoltaic cells. These tiny particles enhance the conductivity of the cells, allowing them to capture and convert more sunlight into electricity. As a result, solar panels are becoming more efficient and cost-effective, contributing to the growing demand for renewable energy solutions. Silver’s unique properties, such as its high reflectivity and electrical conductivity, make it the ideal material for use in solar technology. The continued development of silver nanoparticle technology promises to push the boundaries of what solar panels can achieve in the future.

The Environmental Impact of Silver Nanoparticles in Electronics

While silver nanoparticles are invaluable in advancing technologies like solar panels, they also raise concerns about their environmental impact. Silver is a finite resource, and its increasing demand in the electronics industry could lead to supply constraints. Additionally, nanoparticles can have unintended consequences if released into the environment, potentially affecting ecosystems. However, advancements in silver recycling and sustainable sourcing are helping to mitigate these issues. As the electronics industry continues to grow, it is essential to consider the environmental implications of silver nanoparticle usage and invest in solutions that minimize their ecological footprint.

Conclusion

The use of silver in the electronics industry has revolutionized the production of modern devices. Silver’s superior electrical conductivity and thermal properties make it indispensable for electronic devices like circuit boards and switches. Silver’s role in the electronics industry extends to high-performance applications such as solar panels and printed electronics, where a small amount of silver enhances device efficiency and longevity. As electronics is growing, silver’s importance continues to expand, proving its value in various sectors.

Considering the diverse applications of silver, from solar energy to medical devices, its unique properties make it a critical material in technology today. Silver also offers benefits beyond conductivity, with silver oxide used in batteries and silver nanowires enabling advancements in flexible electronics. As the supply of silver remains stable through silver mining and recycling efforts, its importance in electronic applications will continue to grow, driving innovation across industries.