Introduction

Isolation and test tools are vital for ensuring engineer safety in industrial settings where exposure to high pressure, hazardous gases, or toxic substances is a concern. These tools allow engineers to carry out maintenance, repair, and testing operations by creating isolated sections within equipment or pipelines, ensuring that the work environment remains secure. From combination isolation tools to advanced joint testers, these solutions offer a critical barrier, protecting engineers from unexpected leaks or pressure surges.

As industries evolve, so do isolation tools, with advancements that improve safety, efficiency, and usability. Double block and bleed systems, for instance, provide multiple layers of protection in high-risk scenarios, reflecting the industry’s commitment to safety and innovation. In demanding sectors like oil, gas, and manufacturing, using the right isolation tools is essential not just for workflow efficiency but for the well-being of engineers on the job.

Key Takeaways

- Isolation and test tools are essential for ensuring engineer safety in hazardous industrial settings.

- Combination isolation and joint test tools enhance operational efficiency by combining isolation and testing functions.

- Double block and bleed systems provide additional layers of safety for high-pressure and high-risk applications.

- Advancements in sealing technology are improving the durability and performance of isolation tools.

- Customizable isolation tools offer flexibility to meet the diverse needs of various industrial sectors.

- Prioritizing safety, these tools enable engineers to conduct maintenance and testing tasks with greater confidence.

The Role of Isolation and Test Tools in Engineer Safety

Isolation and test tools play a crucial role in protecting engineers from potential hazards during industrial operations. These tools create a secure environment by isolating sections of piping or equipment, preventing exposure to harmful substances such as gases, vapors, or pressurized fluids. By sealing off specific areas, isolation tools allow for safe maintenance, repair, and testing processes. They mitigate risks associated with hot work and pressure build-up, giving engineers confidence to perform tasks without fear of unexpected leaks or exposure. Industrial operations, especially in sectors like manufacturing and refineries, depend on these tools to ensure safe, controlled testing environments, ultimately prioritizing engineer safety through strategic design and robust application.

Key Safety Features of Isolation and Test Tools

Isolation and test tools come equipped with safety features designed to protect engineers from potential hazards. These tools often include secure sealing mechanisms, durable barriers, and adjustable settings to ensure a safe working environment during maintenance and testing. Additionally, the isolation capabilities help reduce pressure build-up, control the flow of hazardous substances, and provide layers of protection in high-stakes environments. This allows engineers to operate confidently and effectively, particularly in sectors where safety is paramount.

How Isolation Tools Reduce Risk in High-Pressure Operations

In high-pressure industrial environments, isolation tools are essential for minimizing risk. They prevent unexpected leaks and contain potentially harmful substances, ensuring the work area remains secure. By creating isolated sections within piping systems or equipment, engineers can perform their tasks without fear of exposure to gases, vapors, or other hazards. These tools are particularly valuable in industries like oil and gas, where high-pressure operations are common, as they contribute to a safer, more controlled testing environment.

Essential Features to Look for in Isolation and Test Tools

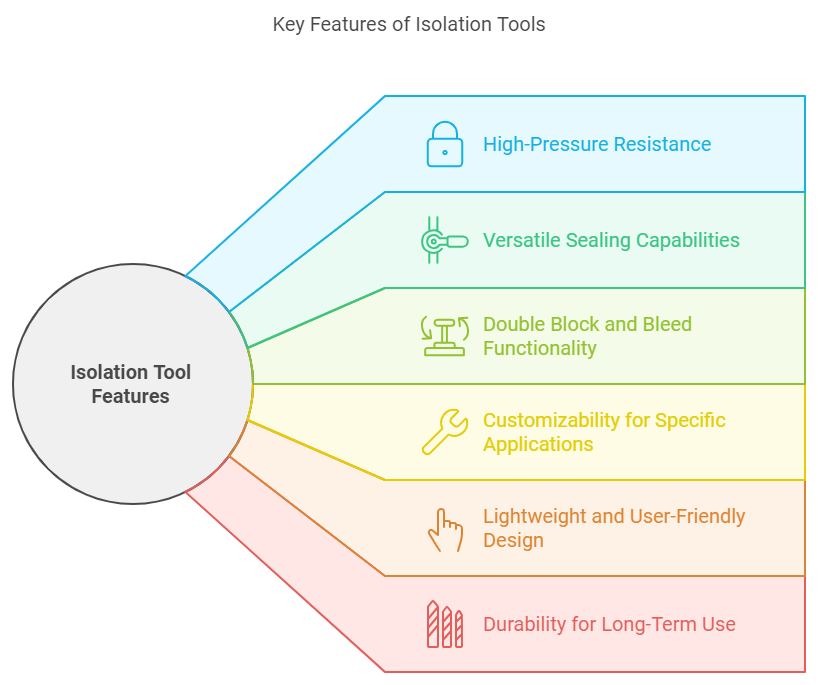

1. High-Pressure Resistance

Isolation tools must withstand high-pressure environments to ensure safety during testing and maintenance. Tools with high-pressure resistance minimize the risk of leaks, making them ideal for industrial sectors with demanding conditions.

2. Versatile Sealing Capabilities

Sealing is a critical function of isolation tools. Look for tools that offer versatile sealing options, such as inflatable or mechanical seals, to accommodate different pipe sizes and shapes, ensuring a tight and reliable seal in any application.

3. Double Block and Bleed Functionality

Double block and bleed systems are designed to provide an extra layer of security in high-risk scenarios. This feature is especially beneficial in sectors where pressure surges or hazardous material leaks could pose significant safety risks.

4. Customizability for Specific Applications

The ability to customize isolation tools according to specific industrial requirements can greatly enhance operational efficiency. Tools that allow customization in size, pressure tolerance, and sealing options cater to unique needs across various sectors.

5. Lightweight and User-Friendly Design

Isolation tools should be easy to maneuver, especially in confined or hard-to-reach spaces. Lightweight and ergonomically designed tools help engineers perform their tasks more effectively and reduce the risk of fatigue or strain.

6. Durability for Long-Term Use

Industrial isolation tools face heavy use and should be built to last. Durable materials and construction increase the tool’s lifespan and reduce the need for frequent replacements, providing long-term value and reliability.

Types of Isolation Tools for Industrial Applications

Industrial applications utilize a range of isolation tools tailored to meet specific operational needs. From combination isolation and joint test tools to custom sealing solutions, these tools are designed to handle demanding environments, allowing maintenance and repair activities to proceed safely. Mechanical isolation tools, for example, use seals and barriers to secure the work area, while inflatable isolation tools offer flexible sealing options for more complex piping systems. Advanced tools like double block and bleed configurations provide additional safety layers in high-pressure tasks. Each tool type aligns with specific safety requirements, demonstrating how tailored isolation solutions support reliable and secure industrial applications around the world.

Overview of Combination Isolation and Joint Test Tools

Combination isolation and joint test tools are highly versatile, offering both isolation and pressure testing capabilities in one tool. These tools are designed for convenience and efficiency, allowing engineers to perform critical testing and maintenance tasks without needing multiple devices. By incorporating sealing and testing functions, they reduce setup time and simplify operations, especially in challenging environments. This overview highlights how combination tools streamline industrial applications while enhancing safety and reliability.

Mechanical vs. Inflatable Isolation Tools: Choosing the Right Solution

Isolation tools come in different forms, including mechanical and inflatable types, each with unique benefits depending on the application. Mechanical tools provide robust sealing options for areas needing rigid containment, while inflatable tools are flexible and ideal for irregular piping systems. Choosing between these tools involves considering factors like pressure, piping configuration, and environmental requirements. Understanding the strengths and limitations of each type allows for smarter tool selection, ensuring both safety and operational effectiveness.

Case Study: Improving Safety and Efficiency in Pipeline Maintenance with Double Block and Bleed Systems

A leading refinery faced challenges with pipeline maintenance due to high-pressure risks and frequent gas build-up in their complex piping systems. To address these issues, they implemented double block and bleed isolation systems to secure work areas during maintenance. This system allowed the refinery’s engineers to isolate specific sections of the pipeline, vent any trapped gas safely, and perform maintenance tasks without the risk of unexpected pressure surges. As a result, the refinery significantly reduced downtime and improved worker safety, allowing maintenance to proceed efficiently with minimal risk to the team.

The use of double block and bleed isolation not only met industry safety standards but also provided the engineers with added confidence in managing high-risk tasks. This practical application highlights the value of using advanced isolation tools in hazardous environments, demonstrating both operational and safety benefits.

Ensuring Safety with Double Block and Bleed Systems

Double block and bleed systems represent a critical advancement in industrial safety, especially for applications requiring precise isolation under high pressure. These systems work by utilizing two isolation points, effectively blocking any potential flow of hazardous substances. The intermediate space can then be safely vented or tested, ensuring no accidental exposure occurs. This method is invaluable in industries where engineers are frequently exposed to high-risk environments, such as pipeline maintenance and testing. By creating a reliable barrier against leaks or pressure surges, double block and bleed systems offer enhanced protection, reinforcing safety protocols and contributing to overall operational integrity in high-stakes settings.

Benefits of Double Block and Bleed in Pipeline Maintenance

Double block and bleed systems are indispensable for pipeline maintenance, as they provide a high level of isolation. This system uses two points of isolation to block potential leaks, with a bleed valve to safely vent any trapped fluids. By securing each side of the pipeline, engineers can safely perform maintenance tasks without the risk of sudden pressure surges. These systems not only enhance safety but also improve workflow efficiency, making them essential in high-risk industries like oil and gas.

Application Scenarios for Double Block and Bleed Isolation

Double block and bleed systems are widely applicable across various industrial settings, especially where pressure control is crucial. Common applications include pipeline testing, pressure management in refineries, and securing work areas during hazardous maintenance activities. These systems provide additional safety in situations where standard isolation might not be sufficient. By understanding the scenarios where double block and bleed isolation is most effective, industries can better protect their workforce and equipment.

“An ounce of prevention is worth a pound of cure.”

— Benjamin Franklin

Advancements in Combination Isolation Tools and Joint Testers

Combination isolation tools and joint testers continue to evolve, driven by innovation and demand for safer, more efficient industrial operations. These tools allow engineers to perform simultaneous isolation and pressure tests, streamlining maintenance processes and reducing downtime. With advanced sealing mechanisms and the ability to withstand high pressure, they provide dual functions essential for pipeline integrity testing and repair. By combining multiple functions into a single tool, combination isolation tools save space and simplify operations, benefiting industries with complex requirements, such as refineries and manufacturing plants. Recent advancements are making these tools more adaptable, customizable, and user-friendly, improving overall safety and efficiency in isolation and testing.

How New Sealing Technologies Improve Tool Performance

Recent innovations in sealing technology have significantly enhanced the performance of combination isolation tools and joint testers. Improved sealing mechanisms provide higher pressure resistance and better adaptability to varying pipe sizes. These advancements not only improve tool durability but also offer increased reliability in high-pressure applications. By focusing on sealing efficiency, engineers can achieve better isolation and testing results, which contributes to a safer and more controlled working environment.

Customizable Isolation Tools for Diverse Industrial Needs

Customization options in isolation tools are helping industries address specific operational challenges. From size adjustments to pressure capabilities, customizable tools allow engineers to tailor isolation solutions to the unique requirements of their work environments. This flexibility is particularly beneficial in industries with diverse needs, such as refining, manufacturing, and transport, where different safety and performance standards must be met. Customizable isolation tools enhance operational efficiency by providing precisely what engineers need for each task.

Conclusion

Isolation and test tools have become indispensable for industrial safety, creating secure work environments for engineers facing potentially hazardous conditions. Through innovations like combination isolation tools and double block and bleed systems, engineers are better protected from risks associated with high pressure and exposure to hazardous materials. These tools provide confidence in maintenance and testing processes, allowing engineers to focus on their tasks without compromising safety.

As industries continue to prioritize safety, advancements in isolation tools will play a pivotal role. Customizable and high-performance isolation solutions are setting new standards for efficiency and protection, meeting the unique demands of high-stakes environments. The focus on robust design and functionality not only strengthens operational workflows but ensures engineers have the reliable tools they need to carry out their work safely and effectively.