Introduction

Valve systems are critical components in industrial operations, regulating fluid flow and pressure to ensure optimal performance and efficiency. By understanding different valve types, such as control valves, check valves, and automated valves, industries can tailor their systems to specific needs. These systems not only enhance fluid management but also minimize energy consumption and operational risks, aligning with modern efficiency goals.

The integration of advanced actuators, real-time monitoring tools, and predictive maintenance strategies has revolutionized valve operations. Sensors and automation systems like SCADA empower operators to make informed decisions, reducing downtime and improving safety. With proper maintenance and strategic upgrades, valve systems can achieve peak performance, delivering long-term reliability and cost savings.

Key Takeaways

- Valve systems play a crucial role in managing fluid flow and pressure in industrial operations.

- Proper selection of valve types and actuators enhances system efficiency and reliability.

- Automation and real-time monitoring tools like SCADA significantly reduce manual intervention and downtime.

- Predictive maintenance strategies extend the lifespan of valve systems while minimizing energy consumption.

- Sensors provide essential real-time data for optimizing system performance and preventing failures.

- Investing in advanced technologies and training ensures long-term operational success and sustainability.

Understanding Valve Systems for Optimal Efficiency

Valve systems are the cornerstone of fluid management in industrial processes, ensuring precise control over flow and pressure. From control valves that regulate variable conditions to check valves that prevent backflow, the type of valve selected can significantly influence operational outcomes. Optimizing these systems involves balancing factors such as fluid dynamics, energy consumption, and system compatibility. With advancements like automated valves and centralized monitoring, industries can achieve enhanced efficiency, minimizing energy waste while maintaining smooth operation. By understanding the core principles of valve systems, operators can align configurations with specific requirements, improving overall performance and reducing potential hazards.

Key Types of Valves and Their Industrial Applications

Valves play distinct roles in various industries, from control valves that manage flow conditions to check valves that ensure one-directional fluid movement. Automated valves are increasingly popular due to their precision and efficiency. Each type of valve serves a unique purpose, requiring careful selection based on system requirements and operational goals. Understanding these distinctions helps operators maximize system performance and minimize potential risks.

How Valve Selection Impacts System Efficiency

The right valve choice can significantly influence a system’s operational efficiency. Factors like fluid type, pressure requirements, and environmental conditions dictate which valves best suit a given process. For instance, automated valves enhance energy efficiency by reducing manual adjustments, while control valves offer superior regulation of flow rates. Proper selection minimizes energy waste, ensures reliability, and promotes cost savings.

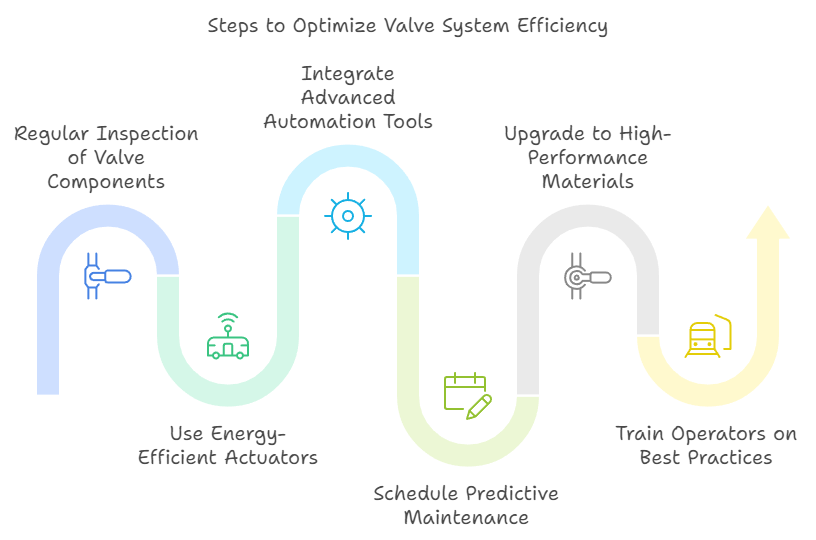

Practical Steps to Optimize Valve System Efficiency

1. Regular Inspection of Valve Components

Conduct thorough inspections of valve components to identify signs of wear, leaks, or damage early. This step helps in avoiding costly repairs and maintaining consistent performance.

2. Use Energy-Efficient Actuators

Choose actuators designed for energy efficiency, such as electric or pneumatic models, to reduce power consumption and operational costs.

3. Integrate Advanced Automation Tools

Implement systems like SCADA to enable real-time monitoring and automated adjustments, ensuring smooth and precise operation.

4. Schedule Predictive Maintenance

Leverage predictive tools that use real-time data to forecast potential issues, allowing for proactive interventions and reduced downtime.

5. Upgrade to High-Performance Materials

Invest in valves made of advanced materials that resist wear and corrosion, ensuring durability and consistent performance.

6. Train Operators on Best Practices

Provide ongoing training for operators to keep them informed about modern valve technologies and troubleshooting techniques.

The Role of Actuators in Enhancing Control and Automation

Actuators are pivotal in converting control signals into mechanical motion, enabling valves to perform with precision. Whether operating manually or through automated systems, actuators offer the flexibility required for various industrial applications. Integration with advanced automation tools like SCADA enables real-time adjustments, optimizing flow rates and reducing manual intervention. Modern actuators are designed to improve energy efficiency, enhance safety, and minimize downtime. Selecting the right actuator type is essential for ensuring compatibility with system demands while achieving seamless and reliable control over fluid dynamics in critical operations.

Choosing the Right Actuator for Industrial Applications

Actuators come in various forms, including pneumatic, hydraulic, and electric, each tailored for specific operational needs. Electric actuators offer precision and energy efficiency, while hydraulic options are ideal for heavy-duty applications. Selecting the right actuator requires evaluating system compatibility, desired control levels, and energy usage, ensuring seamless integration and performance.

The Evolution of Actuator Automation in Modern Industries

Actuators have advanced significantly with automation technologies, providing unparalleled control and reliability. Integration with SCADA systems enables remote monitoring and adjustments, reducing the need for manual intervention. These advancements allow industries to respond to dynamic process conditions efficiently, enhancing both safety and productivity.

Case Study: Revolutionizing Valve Efficiency in a Water Treatment Plant

A leading water treatment facility faced challenges with inconsistent flow rates and frequent downtime due to outdated valve systems. By upgrading to automated control valves paired with electric actuators, the plant achieved precise regulation of fluid flow and pressure. Integration with SCADA systems allowed for real-time monitoring, enabling operators to identify and address inefficiencies proactively.

The facility also implemented predictive maintenance tools, reducing unplanned repairs by 40%. Advanced materials used in the new valves significantly minimized wear and tear, further extending the system’s lifespan. Overall, these improvements led to a 25% reduction in energy consumption and enhanced operational reliability. This case highlights the transformative impact of modern valve systems on industrial performance.

Achieving System Efficiency through Real-Time Monitoring

Real-time monitoring systems revolutionize how industries maintain and optimize their valve operations. By utilizing sensors and SCADA platforms, operators gain instant insights into flow rates, pressure, and valve positioning. This data-driven approach allows for quick adjustments, ensuring optimal system performance and energy savings. Real-time feedback not only prevents inefficiencies like leaks or blockages but also provides predictive maintenance alerts, reducing downtime significantly. Incorporating these monitoring solutions ensures smooth operation, heightened reliability, and proactive management of industrial valve systems, aligning them with modern demands for precision and efficiency.

The Role of Sensors in Providing Real-Time Data

Sensors are the backbone of real-time monitoring systems, offering precise readings on flow rates, pressure, and valve positioning. These insights empower operators to make informed decisions, adjusting valve settings to maintain optimal system performance. The integration of sensors enhances energy efficiency, reduces waste, and prevents costly system failures.

Leveraging SCADA for Predictive Maintenance and Optimization

SCADA systems revolutionize industrial operations by collecting and analyzing real-time data. These platforms help predict maintenance needs, allowing operators to address issues proactively. SCADA’s role in reducing downtime and improving energy savings makes it an indispensable tool for modern valve system management.

Automation applied to an efficient operation will magnify the efficiency. — Bill Gates, Co-founder of Microsoft and Technology Innovator

Maintenance Strategies to Maximize Performance and Minimize Downtime

Effective maintenance strategies are crucial for the longevity and reliability of valve systems. Regular inspections and preventive care help identify issues like leaks or wear before they escalate into costly failures. Predictive maintenance tools, paired with real-time data from automated systems, enhance operational efficiency and reduce downtime. Proper cleaning, lubrication, and calibration ensure valves remain in optimal condition, supporting smooth fluid dynamics. Investing in advanced materials and spare parts further extends system life, while skilled personnel can adapt maintenance routines to specific industrial needs, ensuring consistent performance and minimized interruptions.

Best Practices for Preventive Maintenance of Valve Systems

Preventive maintenance involves routine checks, cleaning, and calibrations to ensure optimal valve performance. These practices help identify and address potential issues like leaks or wear early, preventing system failures. Operators who prioritize preventive measures benefit from reduced downtime and improved operational efficiency.

Incorporating Predictive Maintenance Tools for Longevity

Predictive maintenance tools, driven by real-time data and analytics, offer a forward-looking approach to valve care. By identifying wear patterns and potential issues, these tools enable targeted interventions that extend valve lifespan and reduce repair costs. Predictive strategies are key to achieving sustainable and efficient system operations.

Conclusion

Valve systems are indispensable for maintaining efficiency and safety in industrial operations, providing precise control over fluid flow and pressure. The selection of appropriate valve types and actuators tailored to specific applications forms the foundation of effective system design. When combined with automation and real-time monitoring, these systems deliver enhanced performance, minimize energy consumption, and reduce operational risks.

Regular maintenance, supported by predictive tools, ensures the longevity and reliability of valve systems. By investing in advanced technologies and skilled personnel, industries can optimize their operations and adapt to evolving demands. Prioritizing these strategies fosters sustainable practices and guarantees consistent, high-performance outcomes across diverse applications.