Introduction

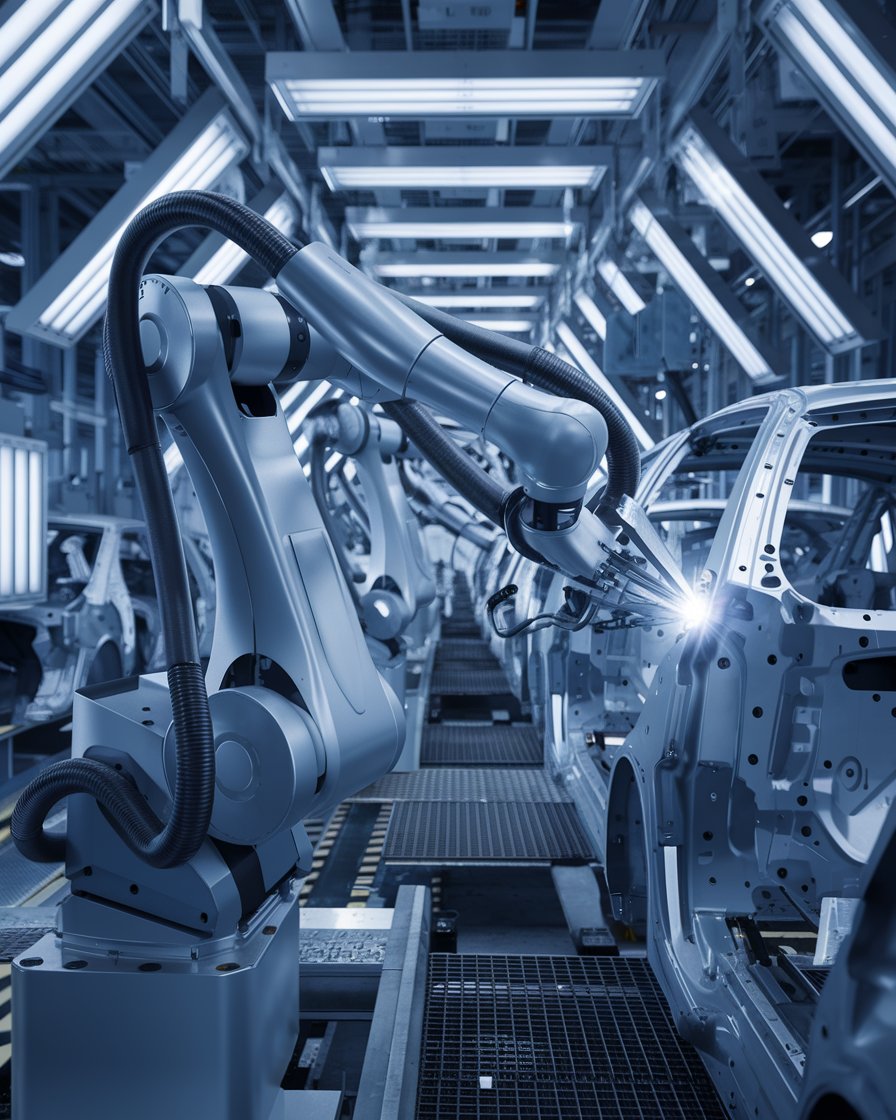

Articulated robots are a cornerstone in modern industrial automation, recognized for their ability to mimic the human arm’s movement using multiple rotary joints and degrees of freedom. These robots are commonly used in tasks like welding, material handling, and pick-and-place operations, thanks to their versatility and precision. In industries like automotive and electronics, articulated robots can perform a wide range of complex tasks with speed and accuracy, making them ideal for improving productivity. With their advanced servo motors and flexible joints, these robots can adapt to various manufacturing processes and environments, enhancing efficiency on the factory floor.

The applications of articulated robots extend beyond simple tasks. These robots are often used in environments that require precise movements, such as in delta robot applications or tasks involving six-axis motion. Whether it’s managing payloads or working within a specific work envelope, articulated robots can handle various industrial tasks. Their ability to automate processes ensures consistency and safety, making them a vital tool across many industries.

Key Takeaways

- Articulated robots closely mimic the human arm’s movement with rotary joints, making them ideal for complex tasks in automation.

- These robots excel in precision tasks such as welding, material handling, and pick-and-place operations in high-speed environments.

- With multiple degrees of freedom, articulated robots offer versatility, performing a wide range of tasks across various industries like automotive and electronics.

- Rotary joints give articulated robots the ability to navigate tight spaces and perform tasks with high accuracy and flexibility.

- Articulated robots increase productivity by automating repetitive processes, reducing human error, and improving efficiency in production lines.

- Their use in hazardous environments ensures safety by reducing risks associated with dangerous tasks in manufacturing and industrial settings.

Understanding the Articulated Robot and Its Role in Automation

Articulated robots play a significant role in modern automation systems, offering enhanced precision and flexibility. With their robot arm and multiple degrees of freedom, these robots can closely mimic the movements of a human arm, making them ideal for applications that require accuracy in manufacturing. Articulated robots are typically used in high-speed production environments like the automotive industry, excelling at tasks such as welding, material handling, and palletizing. Their articulated arm design allows them to perform a wide range of complex tasks across various industries. Though they may be more expensive to maintain, their ability to automate repetitive tasks boosts productivity and reduces the risk of injury to human workers, making them essential in robots that can accomplish multiple operations efficiently.

Key Benefits of Articulated Robots in Industrial Automation

Enhanced Precision and Flexibility Articulated robots offer unmatched precision with their multiple rotary joints and degrees of freedom, allowing them to closely mimic the human arm’s movements. This flexibility is essential in tasks that demand high accuracy, such as welding, assembling, and material handling.

Increased Productivity By automating repetitive and high-precision tasks, articulated robots can significantly boost productivity in industrial settings. Their ability to perform operations with speed and consistency ensures that production lines run efficiently, minimizing downtime and maximizing output.

Versatility Across Industries One of the major advantages of articulated robots is their versatility. They are widely used in industries like automotive, electronics, and manufacturing, handling a range of tasks from pick-and-place operations to palletizing. Their ability to perform in various environments makes them a valuable asset in numerous sectors.

Safety in Hazardous Environments Articulated robots reduce the risk of injury to human workers by performing dangerous tasks in hazardous environments. Whether handling toxic materials or working in high-risk conditions, these robots provide a safer alternative to manual labor.

Adaptability to Complex Tasks With their advanced control systems and servo motors, articulated robots are designed to handle complex tasks with ease. From high-speed production lines to delicate operations, these robots can adapt to different manufacturing environments, improving overall efficiency.

Cost Efficiency Over Time Although articulated robots may have higher upfront costs, their ability to reduce human error, improve safety, and enhance productivity results in long-term cost savings. Their durability and capacity for handling multiple operations make them a cost-efficient solution in the long run.

The Structure of an Articulated Robot

An articulated robot consists of multiple rotary joints, each providing a degree of freedom that allows the robot to move with precision and flexibility. These joints mimic the motions of the human arm, giving the robot the ability to perform tasks in various planes. With the use of servo motors and sophisticated control systems, these robots can be programmed to handle tasks such as welding, assembly, and material handling. The robot’s structure makes it ideal for complex automation tasks, as it can adapt to different environments and workloads with ease.

The Importance of Precision in Robotic Automation

In industrial settings, precision is key to ensuring high-quality production. Articulated robots are designed to perform tasks that require extreme accuracy, such as welding and pick-and-place operations. With their ability to repeat movements with exactness, these robots help maintain consistent product quality. Additionally, articulated robots are equipped with sensors and control systems that enhance their accuracy, making them indispensable in industries like automotive and electronics manufacturing, where even the slightest error can lead to costly defects.

How the Human Arm Inspired the Design of Articulated Robots

The design of an articulated robot is closely modeled after the human arm, with similar joints and degrees of freedom, allowing it to move in various directions. This design gives the robot a high level of dexterity, making it suitable for common applications that require detailed precision. Just like the human arm, an articulated robot has rotary joints, allowing them to reach different positions with speed and accuracy. These robots are the most common in manufacturing environments, where they perform tasks like welding, assembling, and pick-and-place operations. The ability to manipulate objects in different planes makes articulated robots one of the most versatile robot type used across a range of industries, especially in tasks in various industries requiring precision.

Case Study: How Ford Utilized Articulated Robots to Revolutionize Assembly Line Automation

Ford Motor Company, one of the pioneers in automobile manufacturing, integrated articulated robots into their assembly lines to improve efficiency, precision, and safety. In 2015, Ford deployed articulated robots designed to replicate human arm movements for complex tasks such as welding and assembling car parts. These robots, equipped with multiple rotary joints and advanced control systems, were able to mimic the dexterity of human workers while maintaining higher consistency and accuracy.

By using articulated robots, Ford significantly reduced production errors, especially in tasks requiring precision, like installing engine components. The robots’ ability to rotate and move in multiple directions allowed them to perform delicate operations with speed, increasing overall production output by 25%. Additionally, their use in hazardous tasks, such as welding, improved worker safety by reducing direct human involvement in dangerous processes. This case highlights how articulated robots can transform traditional manufacturing environments by boosting productivity and ensuring precision.

Mimicking Human Movements with Robotic Technology

Articulated robots are designed to replicate the flexibility and range of motion found in the human arm. With several joints and degrees of freedom, these robots can rotate, bend, and move in ways similar to human limbs. This makes them highly effective for tasks requiring manual dexterity, such as assembling intricate components or handling delicate materials. The use of advanced control systems allows the robot to perform these tasks with precision and speed, closely mimicking the efficiency of human workers in an industrial setting.

Benefits of Rotary Joints in Articulated Robots

The inclusion of rotary joints in an articulated robot allows for smooth and flexible movement in multiple directions. This feature is essential for performing tasks that require a high degree of precision, such as welding or material handling. Rotary joints give the robot the ability to navigate tight spaces and adjust its position as needed, enhancing its versatility. These joints, combined with the robot’s range of motion, make articulated robots well-suited for a wide range of industrial applications, from simple pick-and-place tasks to complex automation processes.

Practical Applications: When to Use an Articulated Robot in Industry

Articulated robots are widely used in industries where tasks require precision, speed, and flexibility. They are particularly common in automotive manufacturing, where they perform complex tasks such as welding and assembly on production lines. Additionally, these robots are ideal for handling hazardous materials, thanks to their ability to work in environments that may pose risks to human workers. The high level of control offered by their numerous joints and degrees of freedom enables them to perform delicate operations, making them well-suited for tasks like material handling, palletizing, and even high-speed sorting. By using articulated robots, companies can significantly increase productivity while maintaining safety standards.

Common Industries Utilizing Articulated Robots

Articulated robots are widely used in industries such as automotive, electronics, and manufacturing, where precision and speed are critical. In the automotive industry, these robots perform tasks like welding, painting, and assembly with high accuracy. In electronics manufacturing, they are often employed for delicate tasks such as assembling circuit boards or handling small components. The versatility of articulated robots makes them a valuable asset in any industry that requires automated systems for increased productivity and safety.

Complex Tasks Performed by Articulated Robots

Articulated robots are capable of performing complex tasks that would be difficult or dangerous for human workers. These include welding, painting, palletizing, and even surgical procedures in specialized industries. The robot’s ability to move in multiple directions with a high degree of accuracy allows it to handle tasks that require precision, such as material handling and assembly. By automating these processes, articulated robots help increase efficiency and reduce the risk of errors in production.

“Automation is driving the next revolution in manufacturing, empowering machines to take on tasks that once required human precision.” – Elon Musk

Enhancing Efficiency: The Benefits of Using an Articulated Robot

One of the primary benefits of using articulated robots in industrial settings is their ability to improve productivity through automation. These robots can perform repetitive tasks with a level of precision and speed that is hard to match by human workers. Their ability to move in various directions, combined with a wide range of motion, makes them adaptable to many different applications. From welding to material handling, articulated robots offer a major advantage in terms of accuracy and efficiency. Additionally, their use helps to reduce the risk of injury to human workers, as they can handle hazardous tasks that require complex kinematics to govern their motion, improving overall workplace safety.

How Articulated Robots Boost Productivity in Manufacturing

Articulated robots are widely recognized for their ability to enhance productivity in manufacturing environments. Their precision and speed allow them to perform tasks such as welding, palletizing, and material handling more efficiently than human workers. By automating repetitive tasks, these robots free up human workers to focus on more complex and creative aspects of production. Additionally, their ability to work continuously without fatigue ensures that production lines remain efficient and productive.

Safety Advantages of Using Articulated Robots

One of the major benefits of using articulated robots is the improved safety they offer in industrial settings. These robots can perform hazardous tasks, such as handling toxic materials or working in high-risk environments, reducing the risk of injury to human workers. With advanced sensors and control systems, articulated robots can also detect obstacles and adjust their movements to avoid accidents. This makes them a safer alternative to manual labor in industries that involve dangerous conditions or materials.

Conclusion

Articulated robots have revolutionized robotics by providing industries with the precision and versatility necessary for modern automation. Their ability to mimic the human arm through multiple axes and joints allows them to perform complex tasks such as pick and place operations and material handling in environments that require high accuracy. From factory automation to handling delicate tasks in electronics and automotive industries, articulated robots are widely recognized for their efficiency.

Incorporating six-axis articulated designs and servo motors, these robots excel in environments that demand precision, such as cartesian robots for dispensing and assembly tasks. Their flexibility, combined with the capacity to adapt to various types of robots and industrial processes, makes them a cornerstone in many industries. By automating repetitive and hazardous tasks, articulated robots reduce human error, increase productivity, and ensure a safer working environment.