Introduction

Nanotechnology involves manipulating matter at a scale of 1 to 100 nanometers. This allows scientists to create materials and devices with unique properties. These can be used in electronics, medicine, energy, and more. Nanotechnology’s tiny size offers special characteristics not found in ordinary materials.

This article compares nanotechnology applications with traditional electronics materials. Traditional materials include metals like copper and aluminum and organic compounds used in devices. Understanding the differences helps you see why nanotechnology is growing fast and changing industries.

Nanotechnology Applications Explained

What Defines Nanotechnology Applications

Nanotechnology involves working with matter at incredibly small scales, typically between 1 and 100 nanometers. To put that in perspective, a nanometer is a billionth of a meter—so tiny that you can’t even see it with a regular microscope. At this scale, materials behave differently than they do in everyday life, often showing unique physical and chemical properties. For example, nanoparticles of gold don’t look gold; they can appear red or purple depending on their size. Common applications include nanoscale electronics, where chips have components smaller than a virus, or medical uses like targeted drug delivery, where tiny particles can carry medicine directly to diseased cells. The scope is vast—from improving the durability of materials to creating new kinds of sensors.

Advantages Over Traditional Materials

What makes nanotechnology applications stand out from traditional electronics materials? Well, there are a few points worth considering:

- Size and Precision: Nanoscale components allow for packing more functions into smaller spaces. This can lead to smaller, lighter devices that use less power.

- Surface Effects: Because particles have a higher surface area-to-volume ratio, they can react and interact more efficiently. This is something traditional bulk materials can’t match.

- Enhanced Properties: Materials can become stronger, lighter, or more conductive when engineered at the nanoscale. For instance, carbon nanotubes can be stronger than steel yet weigh much less.

- Energy Efficiency: Nanoscale electronics often need less energy to operate, which potentially extends battery life in devices and reduces heat waste.

- New Functionalities: You can get materials that self-assemble or change in response to their environment, features you rarely find in traditional electronics.

You might wonder if these benefits come with trade-offs, such as cost or complexity. They often do. But the potential to revolutionize technology by overcoming the limits of traditional materials keeps driving interest in nanotechnology. It’s a promising yet complex field, and its role in everyday tech might be more significant than you realize already.

Key Characteristics Of Electronics Materials

Common Traditional Materials Used

When we talk about electronics, the materials commonly in play are metals, alloys, and organic conductors. Metals like copper, aluminum, and gold have been staples in wiring and components. Copper stands out for its excellent electrical conductivity. Aluminum, lighter and cheaper, often finds use where weight matters. Gold, while costly, offers excellent corrosion resistance and reliability in contacts.

Alloys such as bronze and brass add mechanical strength or corrosion resistance to metals but may lower conductivity somewhat. Organic materials, though less common for conductivity, are used as semiconductors or flexible components in some devices. Polymers with conductive properties can be seen in newer, flexible electronics.

Material Properties Important For Electronics

Several material properties shape their usefulness in electronics:

- Conductivity: Easy flow of electrons is critical. Metals like copper show very high conductivity, making them ideal for wiring.

- Thermal stability: Electronics parts heat up, sometimes significantly. Materials must withstand these temperatures without degrading.

- Mechanical strength: Often underestimated, strength matters for durability and manufacturing. Brittle materials fail easily under stress or vibration.

The balance of these properties is tricky. For example, alloys may improve strength but decrease conductivity. Your choice depends on the application’s priorities—sometimes it’s a trade-off. Have you noticed how seemingly simple copper wire is actually the result of complex decisions about properties?

Nanotechnology Versus Traditional Materials

Size And Structure Differences

Nanomaterials operate on a drastically smaller scale than traditional electronic materials. We’re talking about sizes from 1 to 100 nanometers—way down at the atomic and molecular level. This tiny scale makes a big difference. The structure of nanomaterials isn’t just smaller; their arrangement and surface area change how they behave. For instance, the increased surface-to-volume ratio affects chemical reactivity and electrical properties.

This matters because traditional materials, often bulk metals or semiconductors, don’t exhibit these quantum and surface effects. Nanomaterials can be engineered almost atom by atom, giving them unique characteristics traditional materials simply can’t match. It’s a bit like having more control, but at scales that can seem almost surreal.

Performance And Efficiency Comparison

Nanomaterials often outperform traditional ones in electronics. For example, carbon nanotubes can carry current better than copper wires without heating up as much. This reduces energy losses and potentially increases device longevity. Also, nanoparticles can help create transistors that switch faster and consume less power.

Of course, it’s not always straightforward. Nanomaterials sometimes present challenges, like complex fabrication or stability issues. Yet, when conditions are right, their ability to enhance speed, reduce size, and save energy can be remarkable.

So, are we ready to fully replace traditional materials? Maybe not just yet. But it’s clear that nanotechnology offers paths to function and efficiency traditional materials haven’t touched yet. The scale and structure differences seem to open doors to new tech landscapes, which may soon become an everyday reality in your devices.

Use Cases Of Nanotechnology In Electronics

Nanotechnology in electronics isn’t just a concept; it’s actively shaping the gadgets you use every day. Think about sensors in smartphones that detect your touch or temperature changes. These often use nanoscale materials to work more precisely than traditional ones. In medical devices, tiny nanosensors monitor vital signs with minimal power, enhancing portability.

Nano-scale transistors are another practical example, powering processors in computers and smartphones. These transistors, made with carbon nanotubes or other nanomaterials, can switch faster while being much smaller than silicon counterparts. This reduces the space chips need—pretty neat when you consider how much functionality fits into your phone now.

Memory chips also benefit from nanotechnology. For instance, resistive RAM (ReRAM) uses nanostructures to store data faster and more reliably. It’s fascinating how such tiny structures hold the promise of dramatically improved storage that consumes less energy.

Seeing the benefits, you might ask: what exactly improves with these nanotech devices? First, smaller size means electronics can be more compact without losing power. Second, less power consumption leads to longer battery life—especially critical for mobile devices. Last, speed enhancements come from quicker electron movement in nanomaterials. It’s not always straightforward, though; sometimes nanodevices struggle with stability or manufacturing challenges. But the potential gains keep driving research forward.

Step By Step Adopting Nanotechnology

Preliminary Research And Testing

When starting to integrate nanotechnology into electronic manufacturing, researching nanomaterials is your first step. It’s crucial to understand properties that emerge at the nanoscale—things don’t behave the same way as bulk materials. For instance, electrical conductivity or strength might shift, sometimes surprisingly. I remember reading about carbon nanotubes, which have exceptional electrical and mechanical traits, but figuring out how to fit them into existing circuits isn’t straightforward.

Initial tests typically involve compatibility checks—how do these materials interact with traditional substrates? You’ll want to look at stability, conductivity, and durability under expected conditions. Sometimes you’ll find materials that initially seem promising but don’t hold up under stress or heat. It’s a mix of lab experiments and simulations, balancing curiosity with caution.

Manufacturing Adjustments Needed

Once convinced about the material’s potential, manufacturing must adapt. Nanomaterials often require handling in cleanroom conditions to avoid contamination—dust particles that are negligible in traditional settings can cause faults here. Equipment might need miniaturization or modification to deposit or shape nanoscale structures accurately. Imagine the challenges for assembly lines designed for larger-scale components suddenly dealing with nanoparticles—it’s a shift, no doubt.

Worker safety also becomes more critical. Nanoparticles behave unpredictably in the air; inhalation risks exist, so ventilation and protective gear protocols get tougher. Plus, quality control now demands new sensors and measurement techniques to detect flaws invisible to conventional inspection tools.

So, integrating nanotechnology isn’t just swapping materials. It means rethinking research, testing, manufacturing steps, and safety. It’s a gradual process with surprises. Are traditional factories ready for this pace of change? That’s something the industry grapples with constantly.

Cost Considerations For Nanotechnology

Material And Processing Costs

Nanomaterials often come with higher upfront material costs compared to traditional metals and organic electronics. Producing nanoparticles or nanoscale structures can be an elaborate process that demands specialized equipment and precise control. For instance, the synthesis of carbon nanotubes or quantum dots requires steps that aren’t quite routine yet, making these materials pricier per unit compared to bulk copper or silicon.

On the other hand, metals and organic components have established manufacturing pipelines backed by decades of refinement, which keeps their prices relatively stable. Yet, it’s not simply a matter of comparing sticker prices for raw materials. Processing nanomaterials can sometimes reduce waste or batch sizes, though these methods might need more energy or time, creating a complex cost balance.

Long-Term Cost Benefits

Now, beyond the initial costs, there’s a potential shift when looking at the bigger picture. Nanotechnology often enables devices that consume less power or have improved performance, which can translate into savings over the lifetime of a product. For example, a nano-enhanced transistor might operate faster and cooler, reducing energy expenses and cooling requirements.

This kind of longevity benefit is something traditional materials rarely match. Even if the investment seems steep initially, the efficiency gains from nanotech components sometimes lead to lower maintenance and replacement costs. Still, it’s not guaranteed — these benefits depend heavily on the application and how well the nanomaterials integrate with existing manufacturing lines.

So, what’s your take? Would you weigh upfront costs more heavily, or consider the operational savings down the line? It’s a choice that varies based on priorities and specific use cases, not an easy one to settle universally.

Common Challenges With Nanotechnology

Toxicity And Environmental Concerns

Nanomaterials bring unknowns when it comes to safety. Their tiny size means they behave differently than the bulk materials we’re used to. For instance, nanoparticles can slip deep into lung tissues if inhaled, causing inflammation or even more serious issues. This isn’t just theoretical—studies on animals show fibrosis and carcinogenic effects linked to some nanomaterials.

You might wonder why these tiny materials can be so risky. Well, it’s their large surface area relative to volume and high reactivity that makes them more active biologically. Even metals considered inert at regular scales, like gold, shift behavior at the nanoscale. Plus, nanoparticles can travel beyond their initial site—getting into the bloodstream or brain, which raises new concerns around exposure.

Environmental effects aren’t fully clear either. Engineered nanoparticles might enter the ecosystem unintentionally, potentially impacting soil and water. There’s still a lot we don’t know about how they accumulate or break down. These unknowns make regulating nanomaterials tricky, requiring careful, case-by-case assessment for each new type created.

Technical And Manufacturing Issues

Scaling nanotechnology from lab to factory floor isn’t straightforward. Handling nanoscale materials demands precision equipment and expertise. Small variations in processing can change the properties entirely, throwing off performance in electronics.

Maintaining consistency is a constant headache. Nanomaterials can clump or aggregate, altering their intended functions. Also, integrating them with traditional manufacturing lines causes compatibility issues—sometimes requiring lengthy adaptation of tools and practices.

Costs explode, too. Producing high-quality nanomaterials at scale remains expensive and time-consuming. And since quality impacts functionality directly, manufacturers face pressure to balance yield with performance rigorously.

So while nanotechnology promises a leap forward, these hurdles in safety and production mean progress is careful, slow, and not without setbacks. Are your ambitions for nano-scale innovation prepared for these realities?

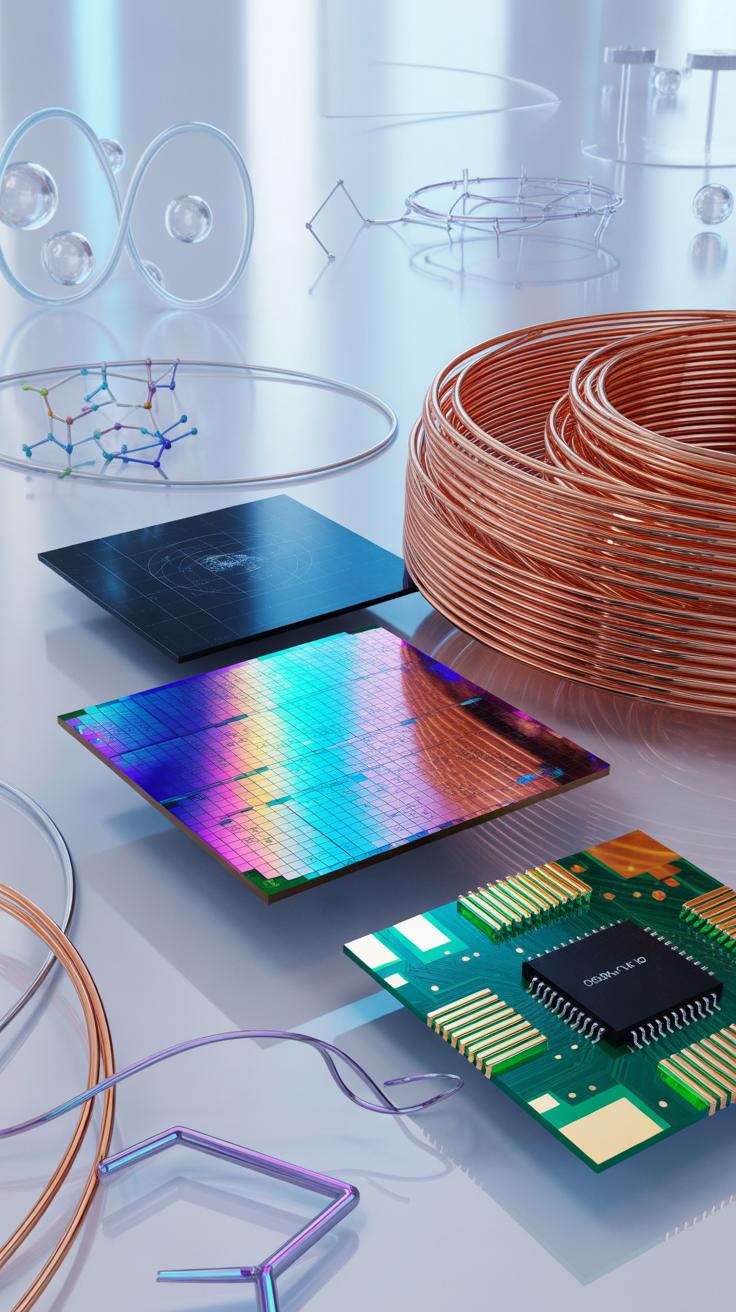

Future Trends In Electronic Materials

When you look ahead in electronic materials research, nanotechnology clearly stands out as a major focus. There’s a lot happening with the tiny scale—really tiny. Scientists are experimenting with new nanomaterials that promise properties traditional materials simply don’t have. These include unprecedented conductivity, flexibility, and strength. For example, carbon nanotubes and nanowires are being developed as components in transistors and sensors that could dramatically shrink device sizes while enhancing performance.

Emerging nanotechnologies, like 2D materials beyond graphene such as transition metal dichalcogenides, bring potential for electronics that bend or even stretch. You might wonder whether these materials will entirely replace silicon in the future or just complement it. It seems more likely they’ll blend together, combining the reliability of traditional semiconductors with the unique properties of nanomaterials to solve challenges single materials face.

There’s also a trend towards integrating nanostructures with existing fabrication processes. Hybrid approaches can enhance things like charge mobility or thermal management without needing a total overhaul of production lines. This could help nanotechnology become more accessible and practical in everyday electronics.

Considering this, your future devices might well be built with a layered approach—traditional materials providing the base, and nanostructured elements boosting speed, efficiency, or resilience. Such combinations often come with trade-offs and complexities. Yet, they highlight how the field is cautiously pushing boundaries, not rushing to discard what works.

What challenges do you think will hold back widespread adoption of these nanotechnologies? Cost, scalability, or perhaps reliability issues? These seem to be the questions researchers face daily. While the future looks promising, it isn’t without its uncertainties.

Deciding Between Nanotechnology And Tradition

Choosing between nanotechnology and traditional materials isn’t straightforward. Your decision hinges on what you really need from the material. Let’s break it down a bit to help you weigh your options without getting overwhelmed.

Checklist For Material Selection

Here are some factors you might want to ask yourself before jumping in:

- Cost: Nanomaterials can be pricey, especially early on. Are you okay with higher upfront investment?

- Performance: Do you need enhanced strength, flexibility, or conductivity that nanotech offers?

- Application Type: Is this for everyday use or specialized high-tech devices?

- Durability and Lifespan: Will traditional materials hold up over time, or does your project demand the resilience nanotech provides?

- Environmental Impact: Are eco-friendliness and safe disposal significant to you?

- Production Scale: Are you producing at a scale where nanotech benefits make sense?

Example Scenarios For Each Choice

Imagine you’re building a standard household appliance. Traditional materials are often enough—reliable and cost-effective. Nanotech might be overkill here, unless you’re aiming for a highly energy-efficient model.

On the other hand, consider flexible electronics like foldable smartphones. Nanomaterials bring unique properties that traditional materials can’t match easily. Or think of medical devices like targeted drug delivery systems—nanotechnology often outperforms traditional methods.

Sometimes, the tried-and-true route fits best, especially if budgets are tight or technology readiness is a concern. Yet, when performance demands stretch conventional limits, nanotech becomes not just appealing but necessary.

So, choosing isn’t just about fancy new tech; it’s about matching your project’s unique goals and constraints.

Conclusions

Nanotechnology offers new ways to build materials with properties that traditional electronics materials cannot match. It enables smaller, faster, and sometimes cheaper devices. This technology is still developing but shows strong promise in many industries.

Choosing between nanotechnology and traditional materials depends on your needs for performance, cost, and manufacturing. Nanotechnology materials are not yet universal but are important players in the future of electronics and beyond. Learning their strengths and limits helps you make smart decisions.